Hand Screen Printing

A behind the scenes look into the process of hand screen printing.

001. Preparation

An artwork has been overlaid onto a silk screen and exposed by an ultraviolet light in order to burn a stencil through the mesh. Before printing commences the screens are examined and touched up to repair any minor imperfections.

002. Colour Mixing

Screen printing inks are mixed according to the design specifications using Pantones as a guide and a creative eye to match them just right.

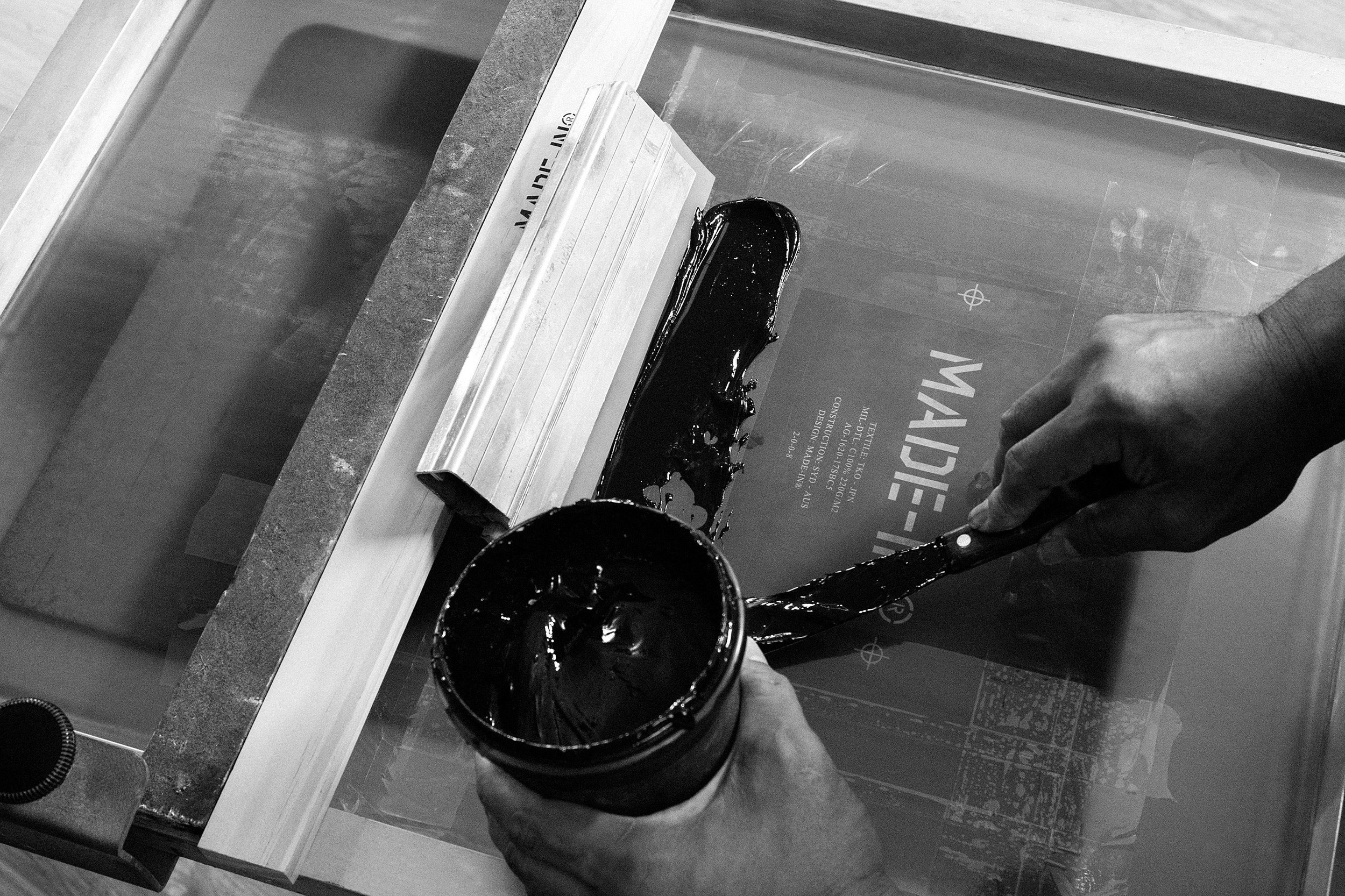

003. Printing

Using downward force and a sliding motion the freshly mixed ink is pressed into the garment through the stencil using a squeegee.

004. Curing

Once the print has been completed the garment must go through a curing process. The garments are fed through an oven with intense heat on a conveyer belt. When cured the ink is dry and permanently set into the fabric.

005. Quality Control

The final stage is to closely examine the products and insure they are up to Made-in® standards, before being presented to our customers